AU 3-Pin Plug Molder 450ST

Model No 型号: 450ST

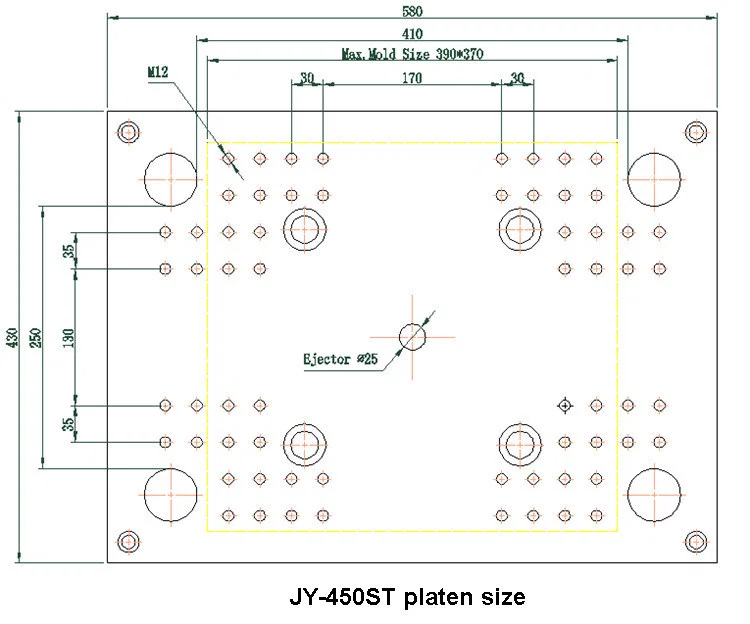

- The AU 3-Pin Plug Molder 450ST is designed for injection molding Australian standard 3-pin power plugs with a 450-ton capacity. This mold ensures accurate and compliant plug molding, essential for manufacturing power cords for the Australian market.

- Inquiry now 立即咨询