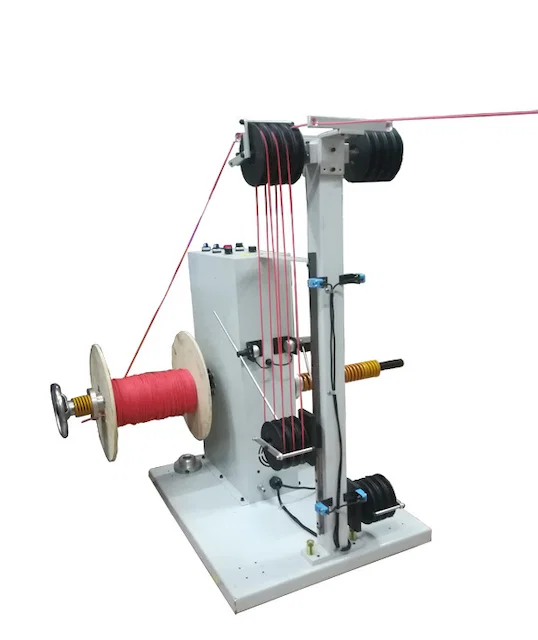

Auto Cut Coil Bind Machine WPM-CRT-02SL

Model No 型号: WPM-CRT-02SL

Specifications

Fully automatic cutting, winding and binding machine for 3D printing consumables WPM-CRT-02SL, wire coiling machine, automatic wire coiling and tying machine.Appearance circle double tie tapeThe inner diameter of the circle is 70-80mmApplicable wire diameter 1.5-1.8mmThe length of the cutting wire is 3-10mThe cutting precision is measured by the winding numberLeave the head length 60-70mmThe tail length is 50-60mm- Inquiry now 立即咨询