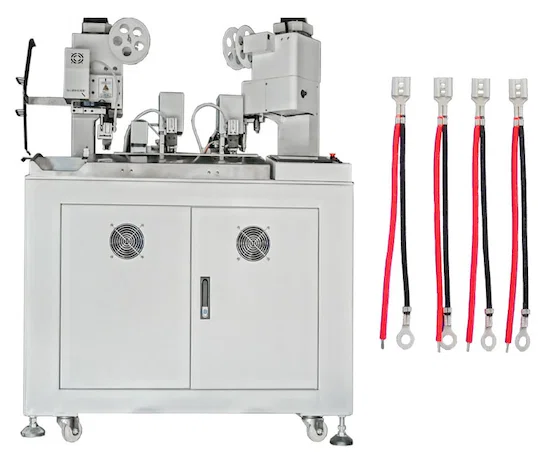

Fully Auto Both Ends 5- Wire Cutting Stripping Twisting Tinning Machine,

Wire Cutting Stripping Tinning Machine,5-wire Cutting Stripping

Tinning Machine, Auto Both Ends Wire Tinning Machine

Specification

The machine is designed to automatically cut, strip, twist, and tin flat cable and single wire, with high efficiency and high accuracy.

(1) For a single wire, we can make the machine outputs 1 or 3 or 5 or 8 wires at one time, the quantity according to the diameter of the wire.

(2) For flat cable, ribbon cable, flat sheathed cable.

Item value

Place of Origin China

Usage cutting stripping twisting tinning

Warranty 1 Year

Efficiency (1 output 3) 32-20AWG, 2700-4000/H

Efficiency (1 output 8) 20-16AWG, 6400-10000/H

Applicable wire AWG18-24 / AWG24-32

Cutting length 30-550mm (min.8mm, customized)

Cutting tolerance 0.2+/-0.02* Length

Stripping length 0-9mm

Twisting length 3-9mm

Tinning length 0.5-9mm

Air supply 0.5-0.7MPa

Features

Machine Dimensions(L*W*H): 1210*770*1370mm.

Machine Weight: 400KG.

Features:

1. Control system: Delta PLC.

2. Cylinder: Germany Mayer.

3. Solenoid valve: Festo, Germany.

4. Screw guide: Taiwan silver.

5. Servo motor drive: Hechuan (optional with Mitsubishi).

6. Pneumatic components: SMC.

7. Temperature control table: Omron.

Advantages:

1. Factory-direct sales, excellent quality, computer touch screen Chinese operation menu is easy to learn and use.

2. Using imported high-precision parts, stable performance.

3. The operation is simple, the length of the wire, the cutting speed, the time of immersion tin, and the number of times of tin dipping are completely touched by the touch screen, which realizes that some wires that are difficult to tin are dipped in the tin.

4. Lead-free tin furnace meets high environmental protection standards; has an automatic tin scraping device, which makes the cut wire bright without tin residue; the tin scraping time can be set to make the tin loss reach the bottom; the tin is dipped at a 90-degree angle, and the tin mouth is even.